Pinnacle Paints® — Equipment Repair, Rentals and Sales

Spray Booth Installation Services

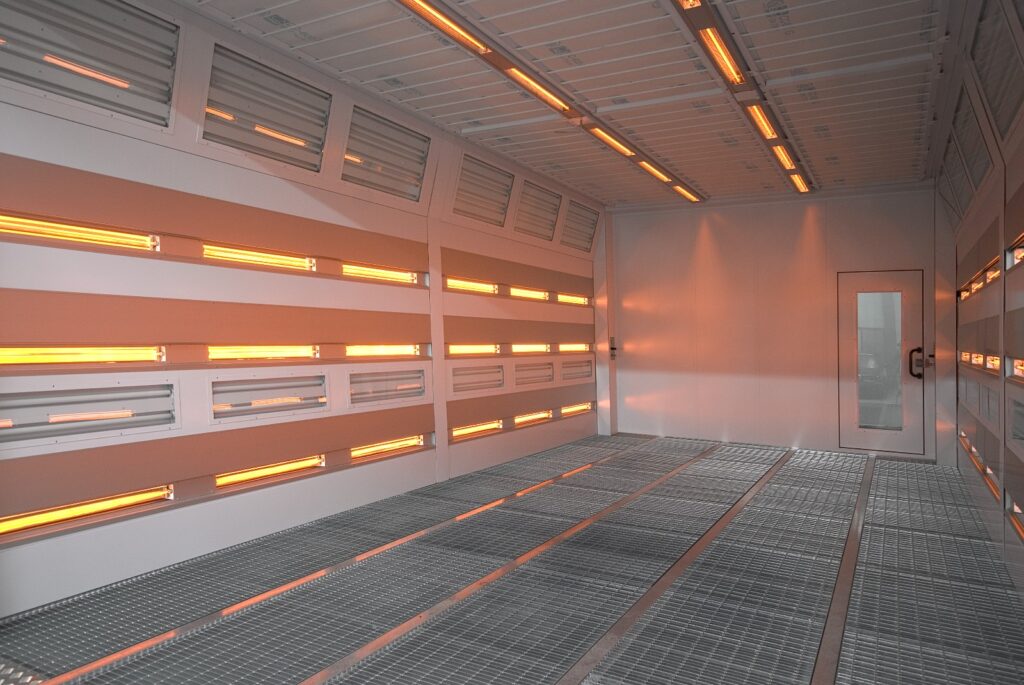

When it comes to building a spray booth, our focus is on creating an environment that maximizes efficiency while minimizing energy consumption. We specialize in designing spray booths that utilize fully-electric heating systems combined with advanced infrared curing technology. These systems ensure faster production times and lower running costs by delivering optimal airflow management and precise temperature control. With the option to divide the booth into discrete zones, you can tailor the environment to your specific needs, further enhancing efficiency and reducing operational costs for smaller jobs.

Our spray booths are equipped with state-of-the-art features to ensure superior performance and durability. From high-performance infrared lamps to a robust stainless steel finish, every detail is engineered for longevity and reliability. The booths are fitted with fully glazed, multi-leaf entrance doors, offering excellent visibility and ease of access. Additionally, we offer hybrid systems that allow you to upgrade existing setups, integrating infrared technology into traditional oil and gas-fired booths. This flexibility ensures that your spray booth not only meets your current needs but is also future-proofed for evolving demands in the industry.

Plural Component Paint Systems: A Superior Alternative to "Hot-Potting"

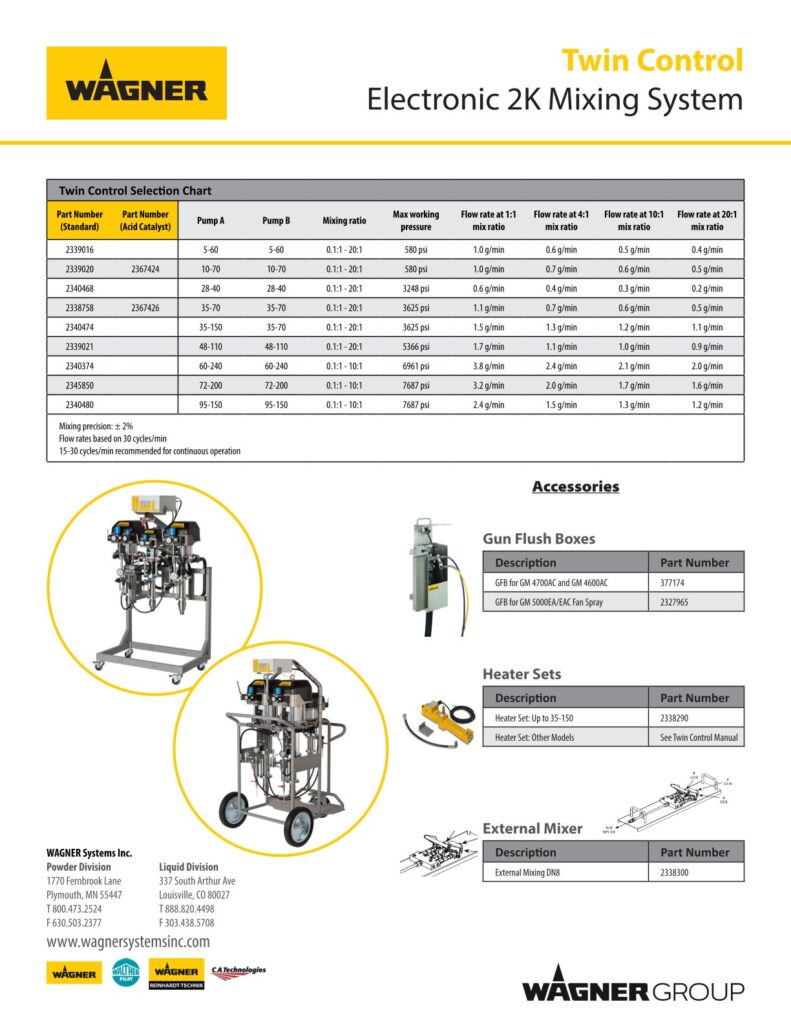

Plural Component Paints involve the use of two or more components that chemically react to harden the paint. While this can also be achieved through “hot-potting,” where the components are manually mixed and then placed in a pressure pot for spraying, there are several reasons why Plural Component Paint Systems offer significant advantages.

Efficiency:

Hand mixing is labor-intensive, repetitive, and, frankly, quite messy. As the demand for skilled painters willing to manually heat, mix, and load paint decreases, the appeal of automated solutions grows. A Plural Component Paint System simplifies this process by automating it with the push of a button, eliminating the need for manual labor and increasing productivity.

Easy Cleanup:

“Hot-potting” not only creates a mess but also requires considerable time to clean up, time that could be better spent on painting. A Plural Component Paint System streamlines the cleanup process—you simply flush the system and shut it down. This efficiency extends to color changes, making transitions quicker and less laborious.

Waste Reduction and Resource Conservation:

One of the key benefits of a Plural Component Paint System is the significant reduction in material waste. Since the components are only mixed within the paint lines just before spraying, there’s no need to mix large batches that might end up being partially discarded due to hardening or cooling. This precise mixing process ensures you use only what you need, conserving resources and reducing waste.

Precision and Consistency:

Achieving accurate and consistent mixing is easy with a Plural Component Paint System. By eliminating the risks of off-ratio spraying and inconsistent results, this system saves you both time and money by reducing costly errors and ensuring every batch is mixed perfectly.

Enhanced Safety:

Safety is a top priority with Plural Component Paint Systems. These systems reduce solvent use, leading to lower emissions and decreased exposure to potentially hazardous chemicals, making for a safer working environment.

Equipment Rental

Pinnacle Coatings Group is a proud distributor of Scanmaskin and has a wide range of floor grinders for all different types of work. Whether you’re working on small-scale tasks or large-scale projects, we have a floor grinder to meet your needs. Our machines are developed with the operator in mind, ensuring ease of use and efficiency in every job.

At Scanmaskin, environmental responsibility is a top priority. We are committed to minimizing our environmental impact in every aspect of our work. That’s why our floor grinders are crafted from high-quality materials, with up to 94% of each machine being recyclable. To further protect our shared environment and deliver top-tier quality, we partner with Swedish suppliers known for their commitment to excellence.

EQUIPMENT REPAIR

Your Personal Service & Repair Department

The team at Pinnacle Painting carries many years of experience in troubleshooting, repairing, and servicing Titan and Graco paint sprayers. They charge 75 USD per hour for repairing products that do not fall within the product warranty, possess the right parts as well as the right expertise to handle the spray equipment, and carry the ability to work with design and build custom spray booths.

We also have the ability to work with you to design and build custom spray booths. These are built to order and can be made to suit whatever your application needs. Submit your spray booth inquiry here.